Tel: 136-9175-1230

Phone: 0755-23208107

http: www.mingruixiang.cn

Website: en.mingruixiang.cn

Add: 4th Floor, Area C, Building 1, Aishang Technology Industrial Park, No. 108, Honghu Road, Songgang Street, Baoan District, Shenzhen, Guangdong Province

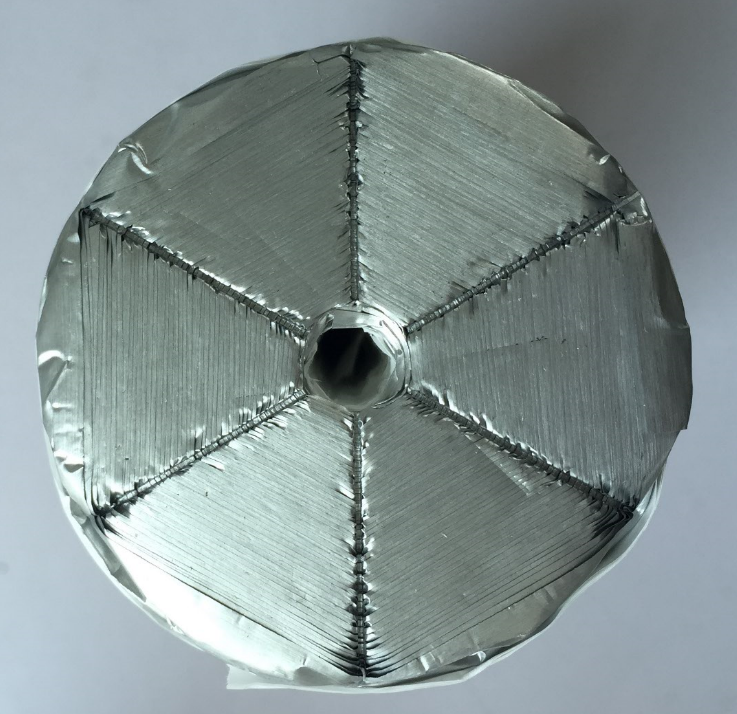

Product Name: batteries shaping machine lithium battery shaping machine

main feature:

*Adopting four-station shaping, so that the copper and aluminum foil base materials are overwhelmed inward one by one in a regular manner, without short circuit rate, so that the base material overlaps and the current collector sheet is better contact and welded firmly;

*With resistance test function, the range can be set to detect products exceeding low resistance value or short circuit;

*When the product is changed, the length adjustment is detected and displayed by the grating ruler, and the adjustment is accurate and intuitive;

*The dynamic design adopts 4-stage shaping, automatic feeding, pressing, pre-shaping 1, pre-shaping 2, flat shaping, resistance test, and discharge;

*PLC control, man-machine interface display, easy to form automation;

*Precise mold design to ensure accurate cell shaping;

*Appearance geometric design, aluminum profile cover is exquisite and beautiful, easy to operate;

technical parameter:

*Applicable products: batteries, supercapacitor cells; *various procedures and process parameters (such as shaping speed, holding time, etc.) are adjustable;

*Slider (pressure head) stroke: 40mm;

*Length positioning accuracy: ±0.03mm;

*Plastic length error: ±0.1mm; *Service life: The normal service life of tooling and mold reaches more than 5 million times;

*PLC process control;

*Capacity: ≧4PPM;

*Utilization rate: 98%;

*Power supply: 220V/50Hz;

*Air source: 0.5~0.7MPa;

*Air consumption: 0.5 m³/min

*Power: 0.5KW;

*Dimensions: L1100mm *W 800mm * H1650mm;

*Weight: 400kg;

Contact: Mr. Luo

Phone: 400-666-9912

Mobile: 136-9175-1230

Address: 4th Floor, Area C, Building 1, Aishang Technology Industrial Park, No. 108, Honghu Road, Songgang Street, Baoan District, Shenzhen, Guangdong Province