Tel: 136-9175-1230

Phone: 0755-23208107

http: www.mingruixiang.cn

Website: en.mingruixiang.cn

Add: 4th Floor, Area C, Building 1, Aishang Technology Industrial Park, No. 108, Honghu Road, Songgang Street, Baoan District, Shenzhen, Guangdong Province

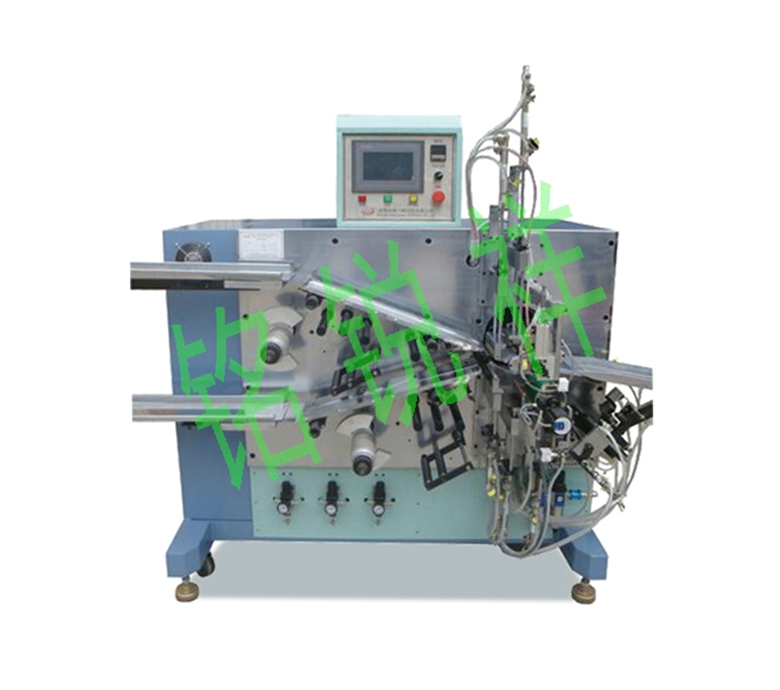

Product name: Semi-automatic square winding machine soft pack battery equipment

The semi-automatic square winding machine is an equipment that can be applied to the winding process of square batteries. The equipment is designed for isolation film roll material feeding, pole piece type feeding, manual film feeding, automatic film pulling, pin insertion and winding. The winding needle adopts a trapezoidal pair-to-plug combination design, and the width of the winding cell can be adjusted within a certain range.

Features |

*For plug-in trapezoidal winding needles, one side is automatically retracted, one side can be pulled out, and the winding speed can be set;

*The size compatibility design of the winding cell, the length of 30-100mm can be realized by adjusting the clamp, the winding needle can be adjusted within 10mm of the width change, and the winding needle must be replaced if it exceeds;

*PLC control, touch screen operation, all parameters can be set, design full automatic cycle stepping function, can step back step by step;

*Optional automatic tape machine to assist tape tape;

*Single vertical plate structure, can be applied to the winding process of square lithium ion battery;

*Isolation film roll feeding, passive tension control, adjustable tension;

*Slice-type pole piece feeding, guide plate guides, manual feeding needle, vacuum assisted suction during winding;

technical parameter |

* Winding size: width 40-100mm, length 30-100mm, thickness 10mm

* Winding accuracy: neatness is better than 0.5mm

*Needle winding form: double-insertion trapezoidal winding needle, standard width 60mm

*Guide length: 1000mm, pole piece can be slightly longer

* Film cutting method: automatic cutting

*Tension control: can be set within 150g

*Width adjustment: Manually adjust the winding needle to achieve adjustment within 10mm, and the excess part needs to be replaced

* Winding speed: adjustable on the touch screen

*Positive and negative ears: position can be set by motor unwinding

*Adhesive tape placement: provide automatic tape dispenser, manual tape

*Air source: 0.5~0.8MPa compressed air

*Power source: voltage single-phase AC220V±10% (110VAC can be customized), frequency 50Hz/60Hz, power 1KW

*Equipment size: L1300mm*W700mm*H920mm

*Weight: about 360KG

Contact: Mr. Luo

Phone: 400-666-9912

Mobile: 136-9175-1230

Address: 4th Floor, Area C, Building 1, Aishang Technology Industrial Park, No. 108, Honghu Road, Songgang Street, Baoan District, Shenzhen, Guangdong Province